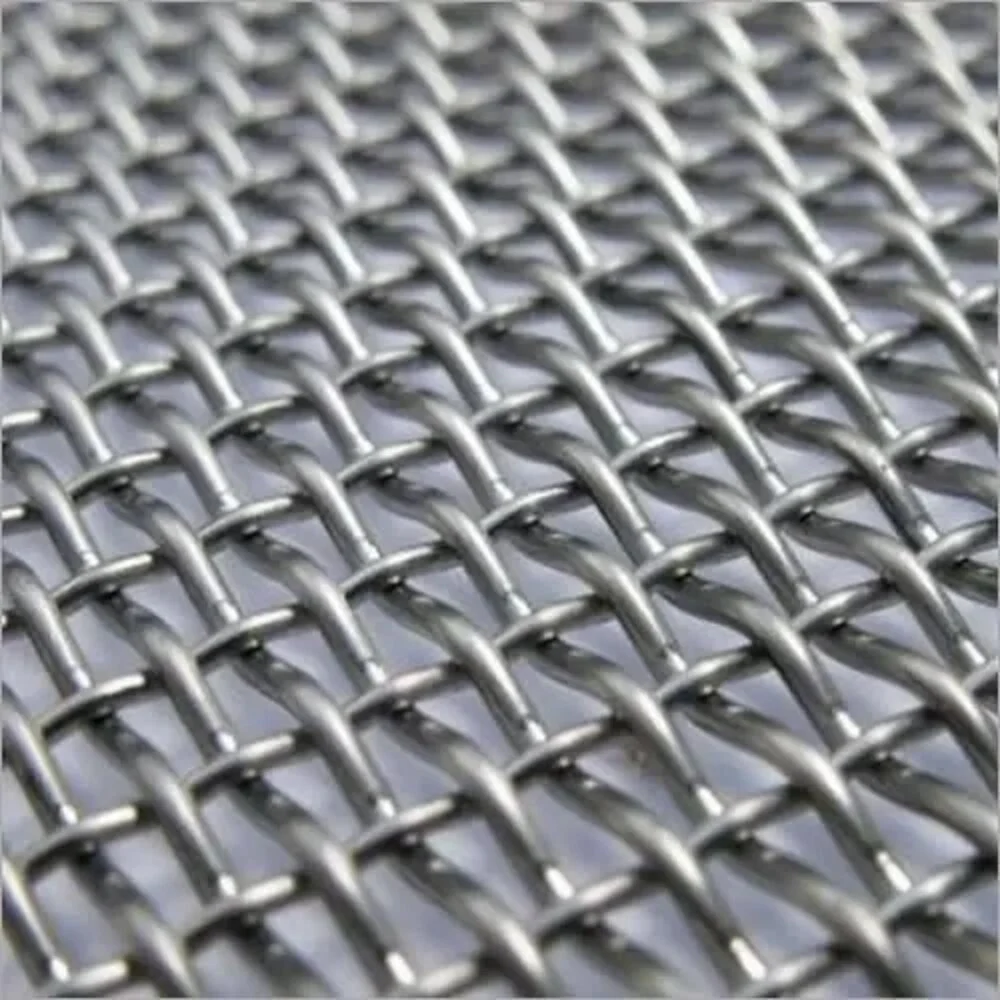

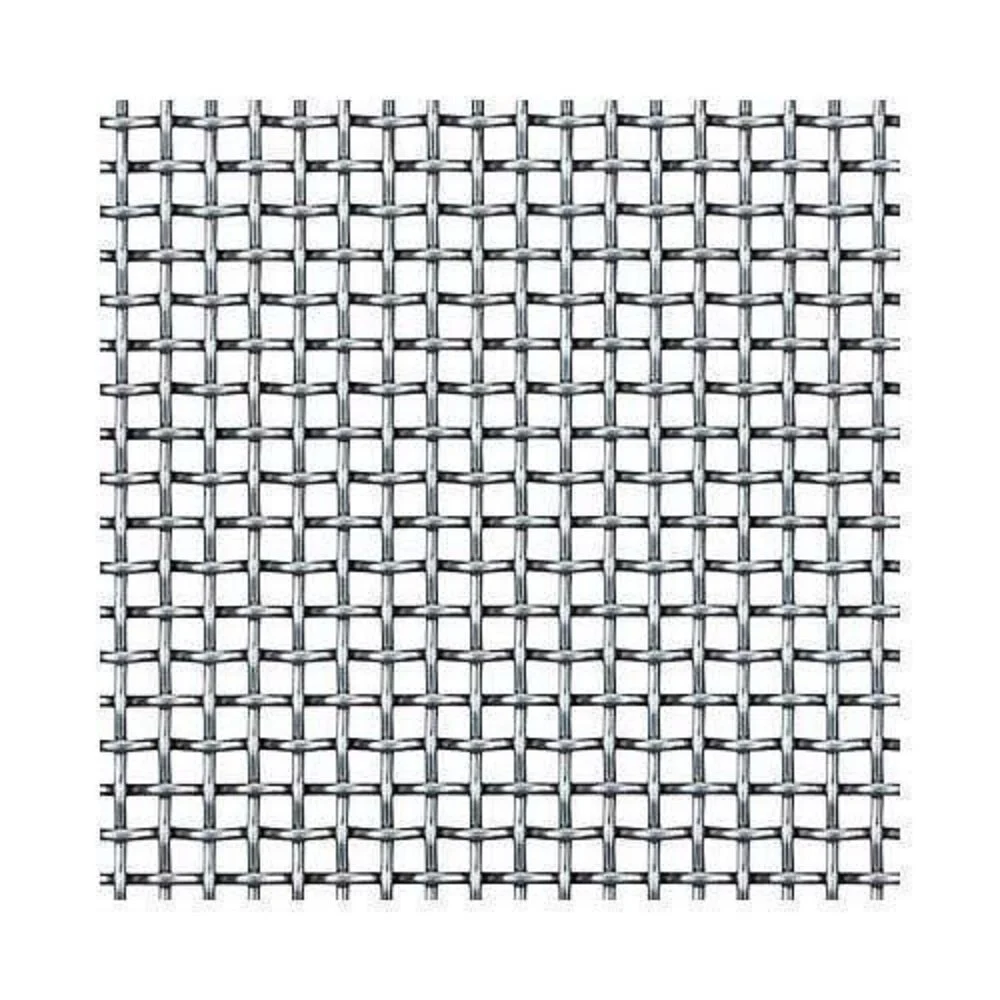

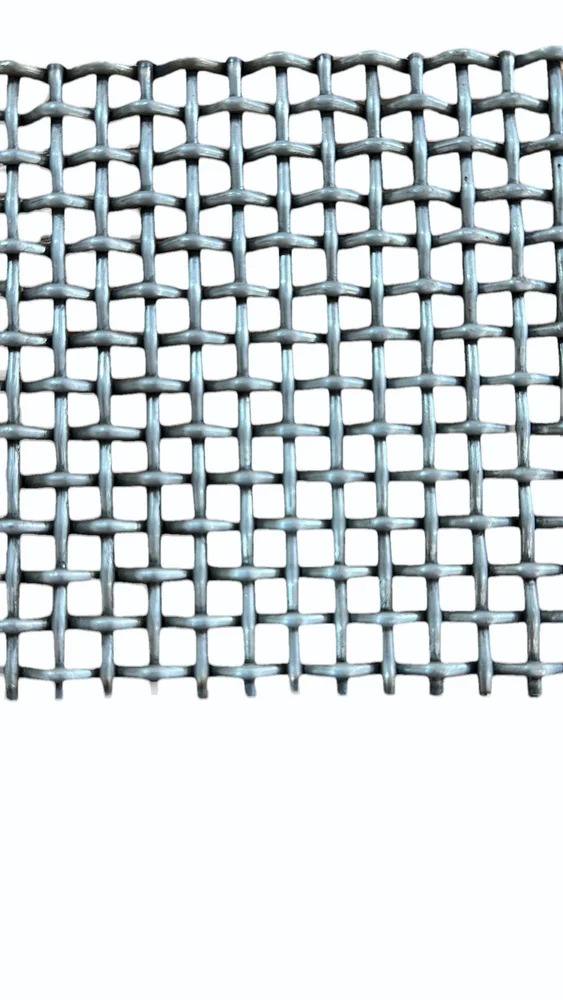

Stainless Steel 316 Wire Mesh

| Material Grade | SS316 |

| Thickness | 16 Gauge (1.58 mm) |

| Hole Shape | Square |

| Weave Type | Plain |

| Color | Silver |

| Usage/Application | Aquaculture Industries, Medicinal Purpose, Food Industries |

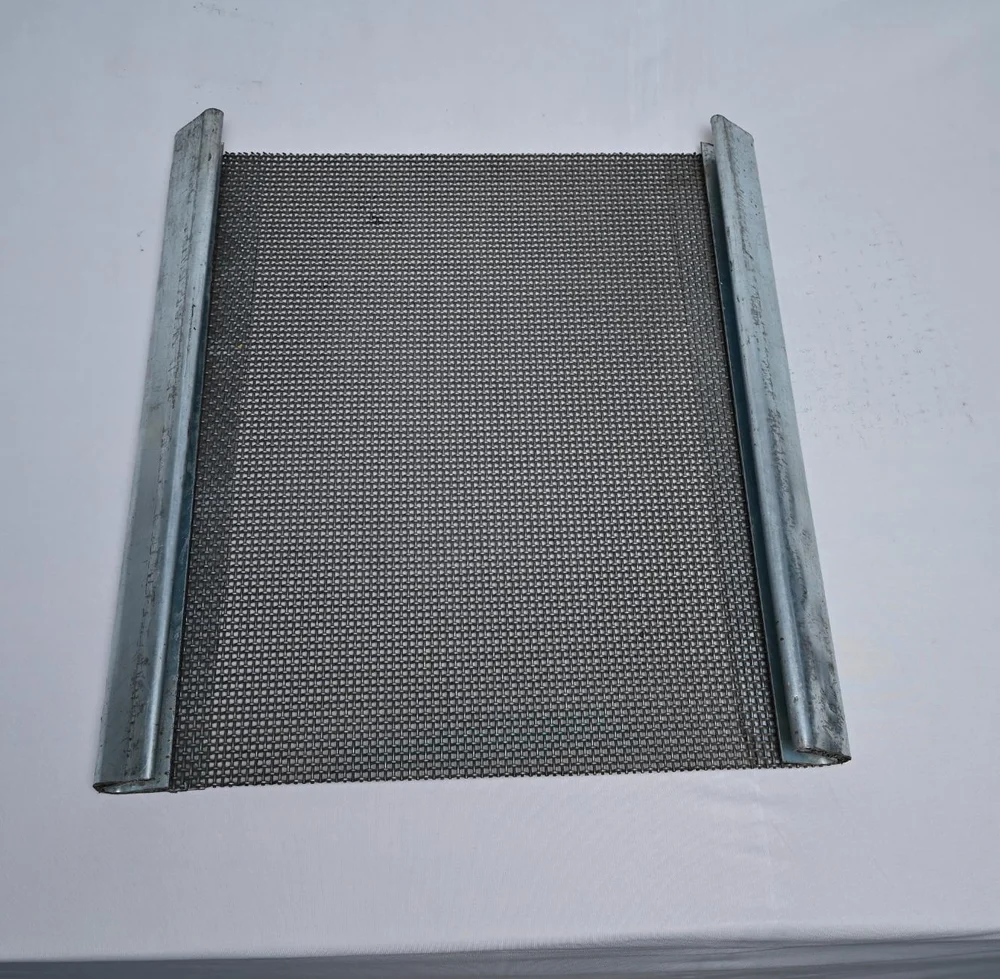

We craft high-quality wire mesh from diverse materials like Stainless Steel 304, 316, 202 tailored precisely to your customer requirements. From welded to woven, and hexagonal mesh, our products are perfect for construction, filtration, fencing, and industrial uses. Expect unmatched quality and durability in every roll or pices.

Wire mesh is an incredibly versatile product, used in a vast array of applications across almost every industry, as well as in residential and decorative settings. Its adaptability comes from the ability to vary the material, wire diameter, mesh opening size, weave pattern, and surface treatment.

Here's a breakdown of common wire mesh applications:

Industrial & Heavy Duty Applications:

- Screening and Sieving: This is a primary application, especially for spring steel wire mesh.

- Crushing & Mining: Used as vibrating screen decks in crushers (jaw, cone, impact) and screening plants to separate aggregates (sand, gravel, stone), ore, coal, and other bulk materials by size. This is where spring steel wire mesh excels due to its abrasion resistance and ability to withstand heavy impact.

- Quarries: Similar to mining, for grading and sizing quarried stone.

- Recycling: Separating different types of waste materials (e.g., construction and demolition waste, plastics).

- Food Processing: Sieving flour, grains, spices; filtering liquids (e.g., juices, oils). (Often stainless steel for hygiene).

- Pharmaceuticals: Sifting powders and granules, filtration.

- Chemical Industry: Filtration of liquids and gases, catalyst support, particle separation.