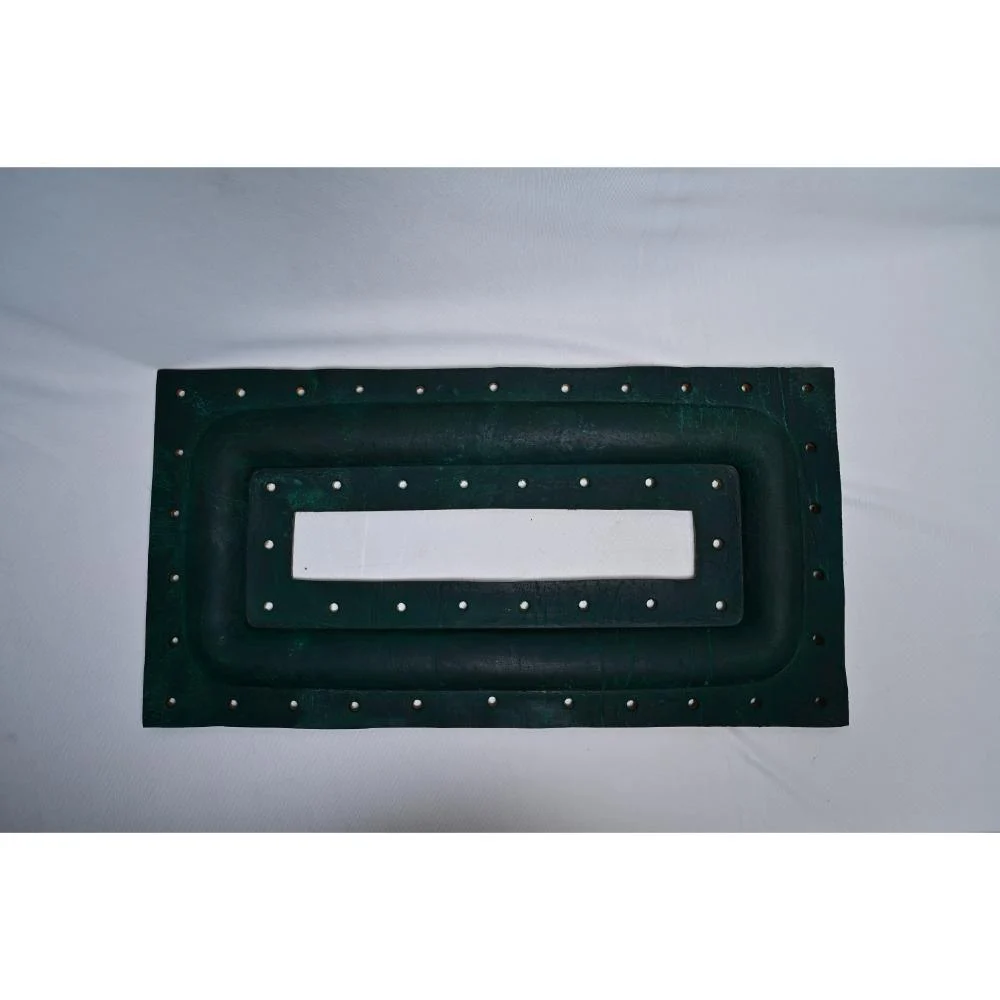

20x12 Crusher Leather Diaphragm

| Diaphragm Diameter | more than 20 inch |

| Usage/Application | Machinery |

| Minimum Order Quantity | 5 Piece |

Leather Diaphragms for Crushers: Unmatched Durability for Extended Performance

Leather diaphragms are an excellent choice for certain crusher applications, particularly in oil-type jaw crushers, where they serve as a vital sealing element to prevent oil leakage. While rubber diaphragms are also common, leather offers a significant advantage in terms of lifespan, often lasting 3-4 times longer than rubber (neoprene) diaphragms. This extended durability translates directly into reduced downtime, lower replacement costs, and increased operational efficiency for your crushing operations.

Why Choose Leather Diaphragms?

- Exceptional Lifespan: This is the primary benefit. High-quality leather diaphragms, especially those made from treated buff leather, are engineered to withstand the demanding conditions within crushers for significantly longer periods than their rubber counterparts. This means fewer interruptions for maintenance and replacements.

- Reliable Sealing: Leather provides a consistent and effective seal for oil tanks in jaw crushers, preventing lubricant loss and contamination.

- Durability and Flexibility: Treated leather offers a unique combination of strength and flexibility, allowing it to perform reliably under pressure and movement.

- Cost-Effectiveness in the Long Run: While the initial cost might be comparable or slightly higher than rubber, the drastically extended lifespan of leather diaphragms leads to substantial savings over time due to less frequent replacements and reduced labor costs.

- Consistent Performance: Known for their stable performance over their long service life, ensuring smooth and reliable operation of your crusher.

Common Applications:

- Oil-type Jaw Crushers: Primarily used for sealing oil tanks, a critical function to maintain lubrication and prevent damage.

- Stone Crushers: Applicable in various stone crushing machinery where a durable and reliable diaphragm is required.

- Common Sizes: Available in various sizes, with examples like 12-inch, 15-inch, 18-inch, and larger rectangular diaphragms suitable for Oil type Jaw crusher Like 16x9, 20x12, 30x15, 36x8,36x24, 36x30,30x24 42x6, 42x8, 42x9,42x10,42x36, 48x36.